1. Introduction to hydraulic retarder

1.1 what is hydraulic retarder

Automobile brake system is one of the most important systems in the safe driving of automobile. With the development of engine technology and the improvement of road conditions, the vehicle's driving speed and single running distance have been greatly developed, and the driving kinetic energy has been greatly improved. Therefore, the traditional friction plate brake can not meet the needs of long-term and high-strength work. Due to the frequent or long-term use of the service brake, the brake efficiency of the overheated friction plate declines, which leads to the brake failure and threatens the driving safety. Vehicles also have increased transportation costs due to frequent replacement of brake shoes and tires. In order to solve this problem, all kinds of vehicle auxiliary braking system have developed rapidly, hydraulic retarder is one of them.

The structure of the hydraulic retarder is basically the same, which is composed of rotor, stator, working chamber, input shaft, heat exchanger, oil storage tank and shell. Its installation mode is generally divided into two types: series connection and parallel connection with the transmission shaft. It can be installed before and after the transmission in series. If parallel connection is adopted, the retarder and transmission shall be installed as a whole. For vehicles equipped with automatic transmission with torque converter, the original transmission system has been equipped with oil tank, oil pump, radiator and other components. Therefore, it is cheaper to install Hydraulic Retarder on buses and freight cars equipped with automatic transmission.

1.2 what are the advantages of vehicle mounted hydraulic retarder

1、 High braking torque. The maximum braking torque can reach 4000N.m. The braking torque capacity of eddy current retarder is mainly 2000-3000n. M. In order to ensure the reliable transmission of huge braking torque, the hydraulic retarder should generally match the end tooth transmission shaft with stronger bearing capacity.

2、 Light weight, small installation volume. Taking Voith hydraulic retarder as an example, from 2000-4000n. M, the weight is only 65kg-85kg, while the weight of eddy current retarder is 175KG at 2000N. M and 450kg at 3000n. M. Because of the huge weight, eddy current retarder needs a separate mounting system to carry its weight. The hydraulic retarder does not need any suspension, and can be directly installed on the transmission housing or the drive axle housing.

3、 Strong continuous braking efficiency. The brake heat decay is the bottleneck of the eddy current retarder, which makes the eddy current retarder unable to brake for a long time. After braking continuously for more than 10 minutes, the rotor of the eddy current retarder will show a red hot state, and start the over temperature protection and lose the ability to continue to slow down. On the contrary, the hydraulic retarder can use the engine cooling system to dissipate heat and ensure that the working temperature does not exceed 125 degrees. The strong continuous cooling ability ensures the continuous braking efficiency. Even if the brake is applied continuously for a long time, its braking efficiency will not decline at all.

4、 Low energy consumption. The eddy current retarder generally needs 112a-180a (3000Nm) current, so the huge power consumption is unbearable for the generator, so the vehicle equipped with the eddy current retarder also needs to install a large generator. This not only wastes the power of the engine, but also presents a severe challenge to the already crowded engine compartment. The hydraulic retarder only needs 1A current for the control circuit, and the power consumption is the same as that of a sound, so the engine power will not be wasted.

5、 "Studio" temperature is low. The working temperature of the eddy current retarder is as high as 500 ℃ - 800 ℃, the rotor surface is in a red hot state, and the relatively closed chassis can not provide it with enough strength of cooling air flow. If the heat dissipation is poor and close to flammable objects, it is very easy to cause the vehicle fire. Moreover, there was a time when the temperature of the rotor of the eddy current retarder was too high, which led to the self ignition of the vehicle due to the burning of the plastic bag rolled into the chassis. On the contrary, the hydraulic retarder can keep the working temperature at about 125 ℃, which has no adverse effect on any adjacent parts. Even after a long downhill, it can stop and park immediately without thermal deformation. There is no reduction in the retarding capacity of the restart vehicle.

2. Hydraulic retarder proportional valve

2.1 function of hydraulic retarder proportional valve

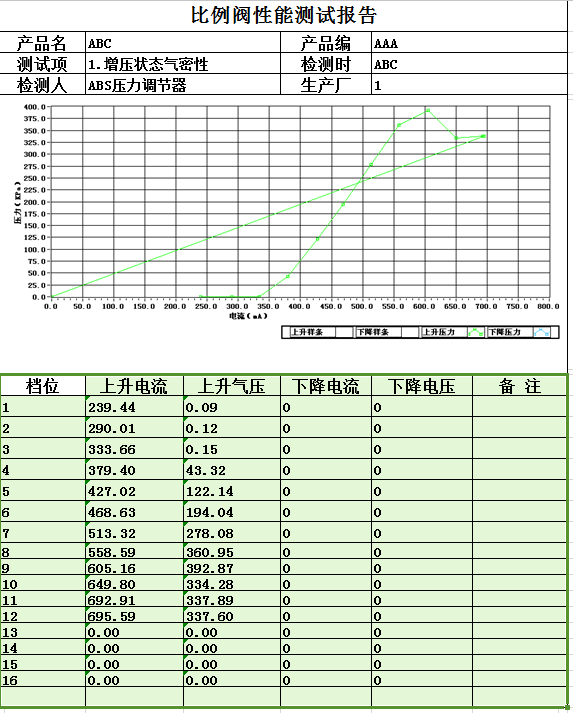

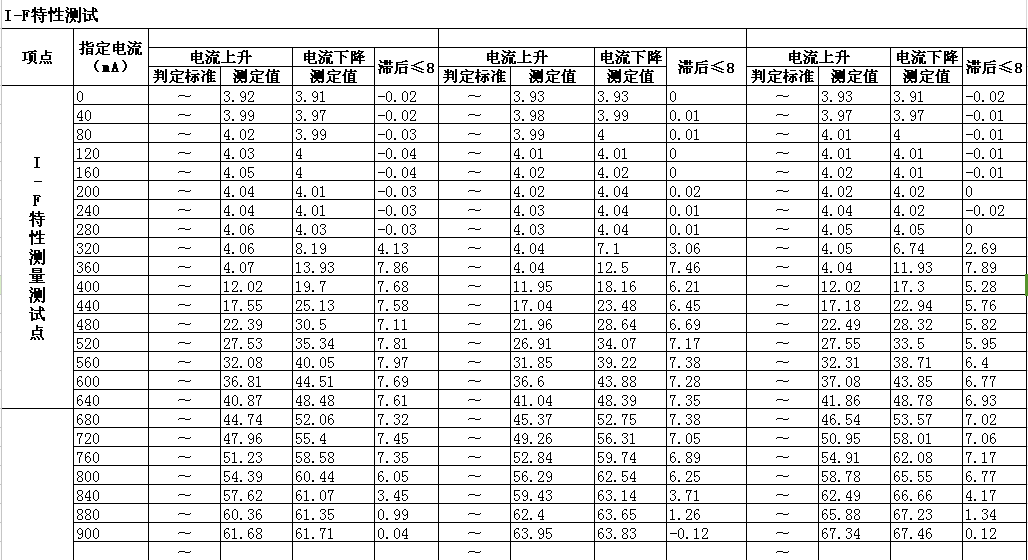

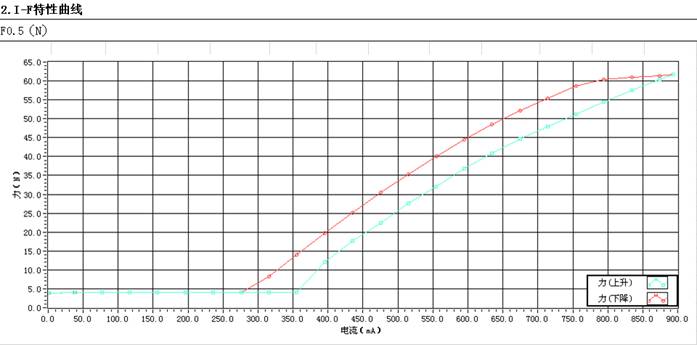

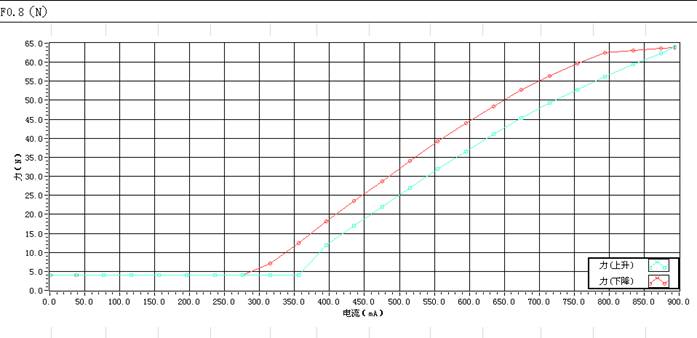

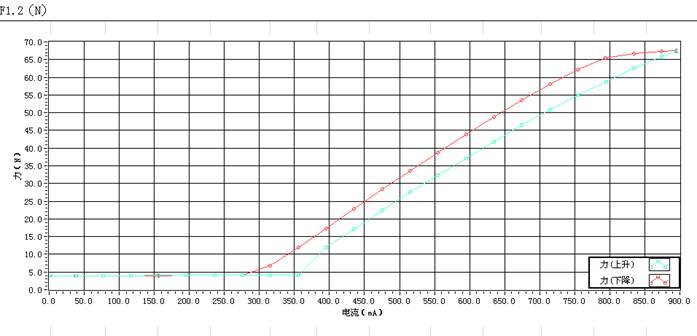

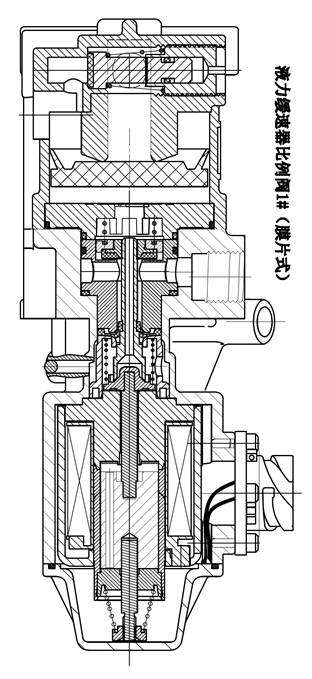

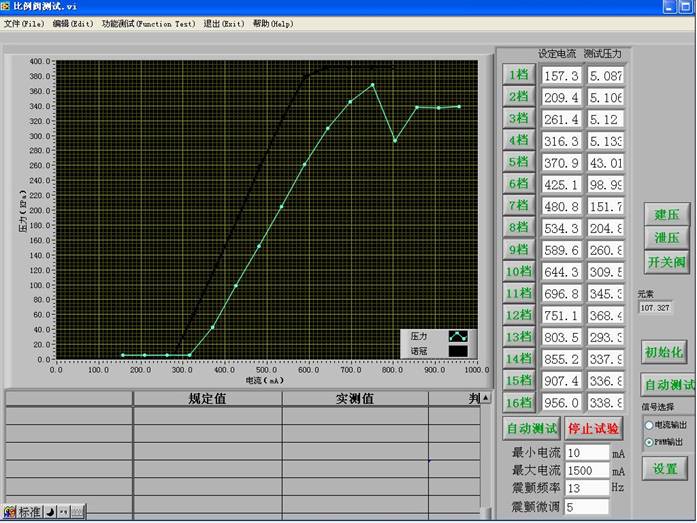

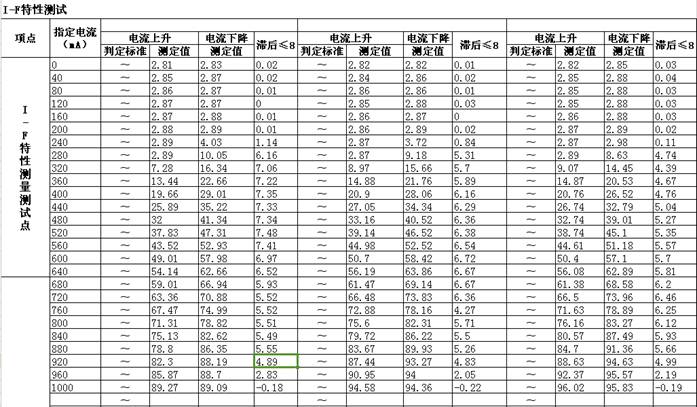

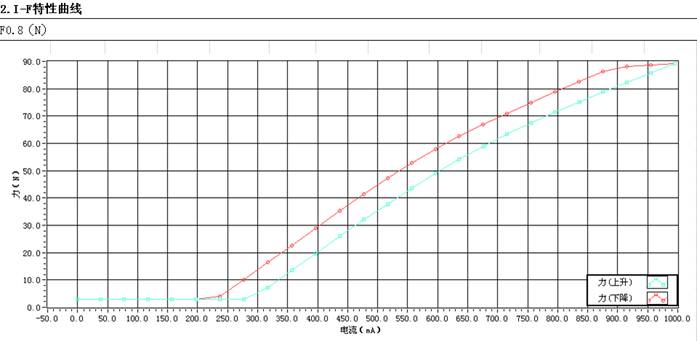

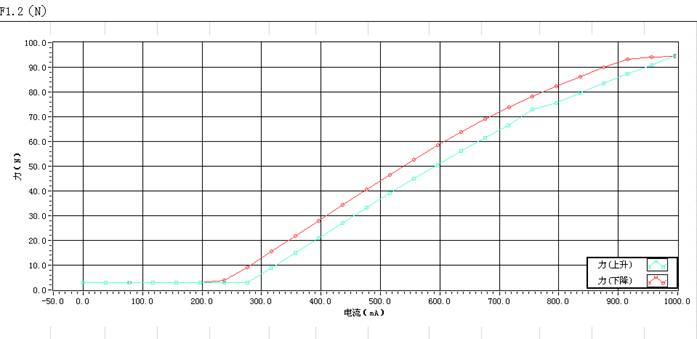

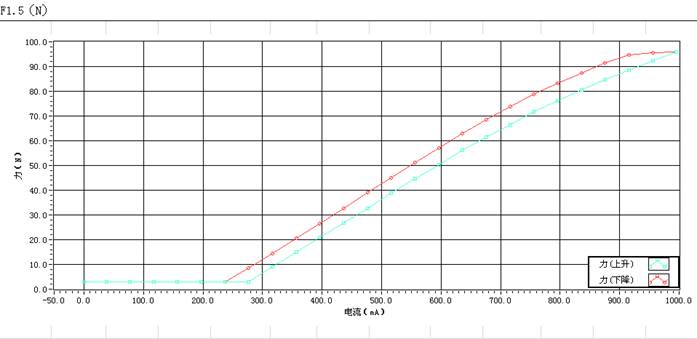

When the hydraulic retarder works, it is generally divided into five gears according to the required braking force. The amount of oil filled into the retarder in each gear is different, and the amount of regulating oil is controlled by the exhaust amount of the proportional valve, After the driver selects a gear, the retarder controller will give a current signal to the proportional valve according to the need. The proportional valve can adjust the exhaust volume according to the change of current, so as to obtain different braking forces.

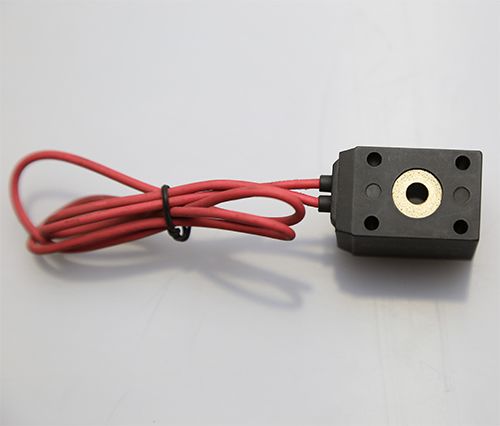

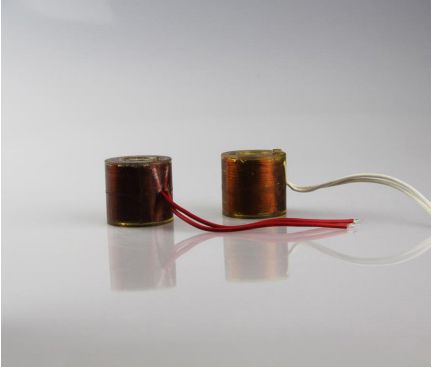

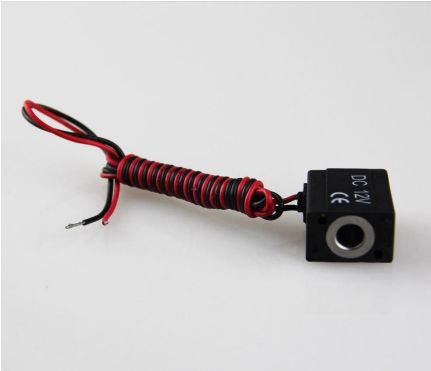

2.2 hydraulic retarder proportional valve of our company

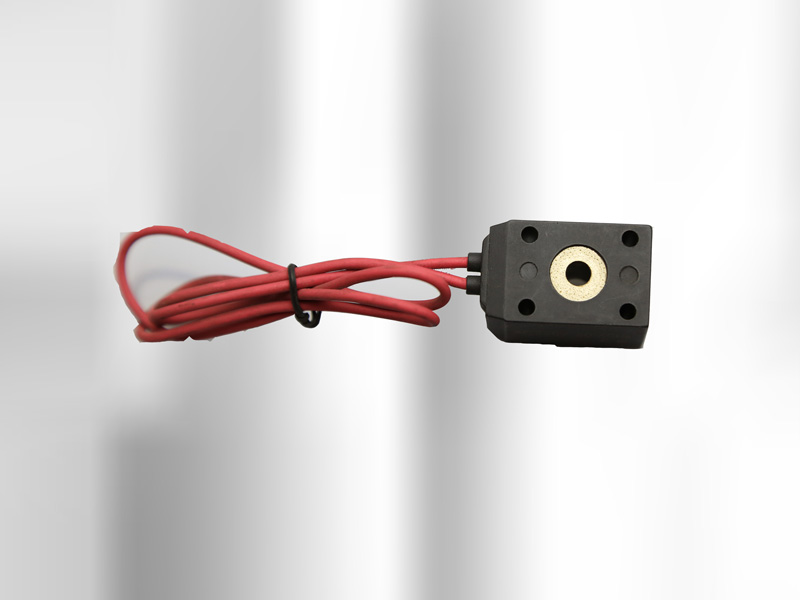

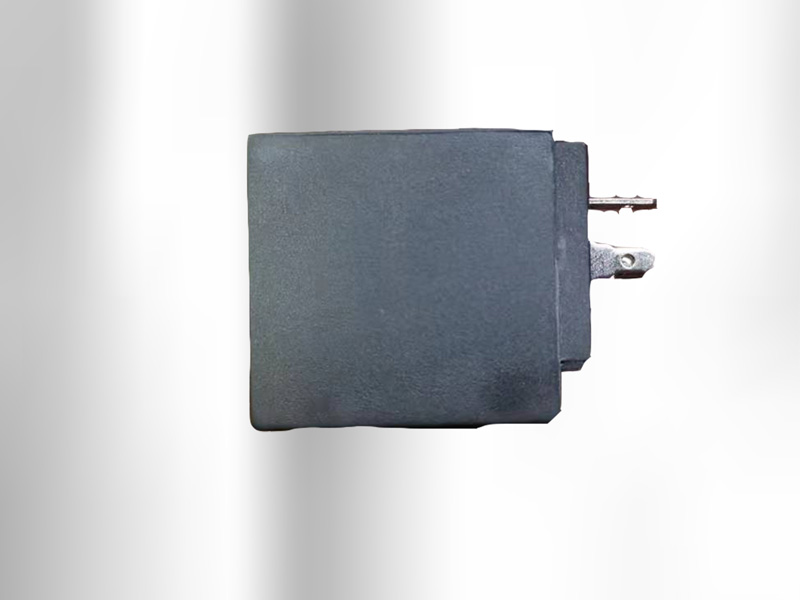

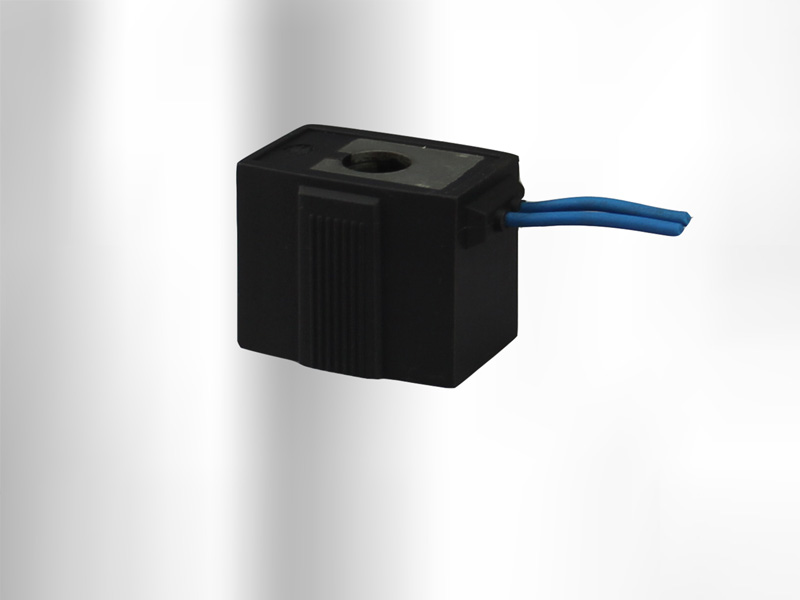

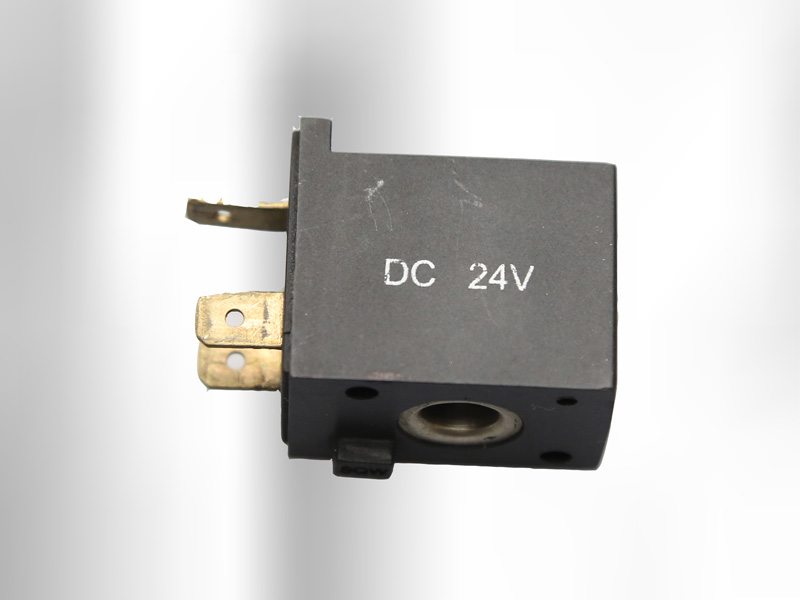

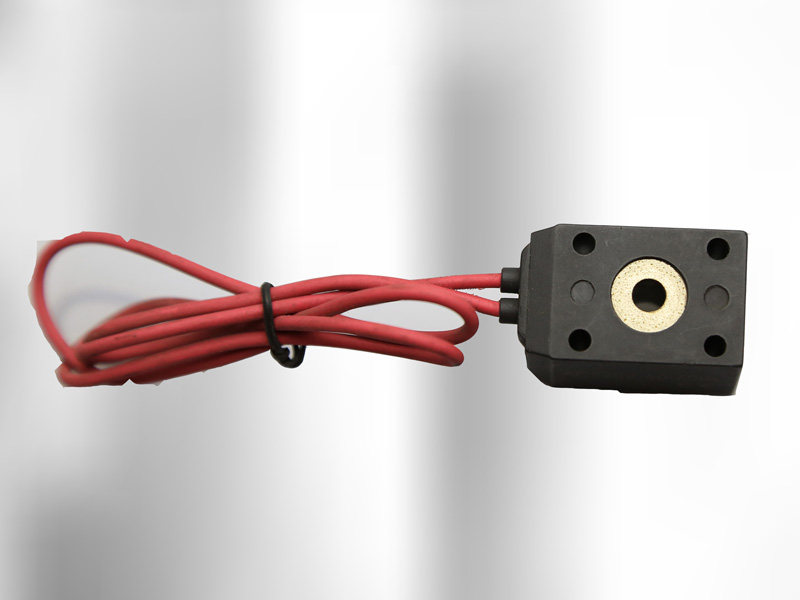

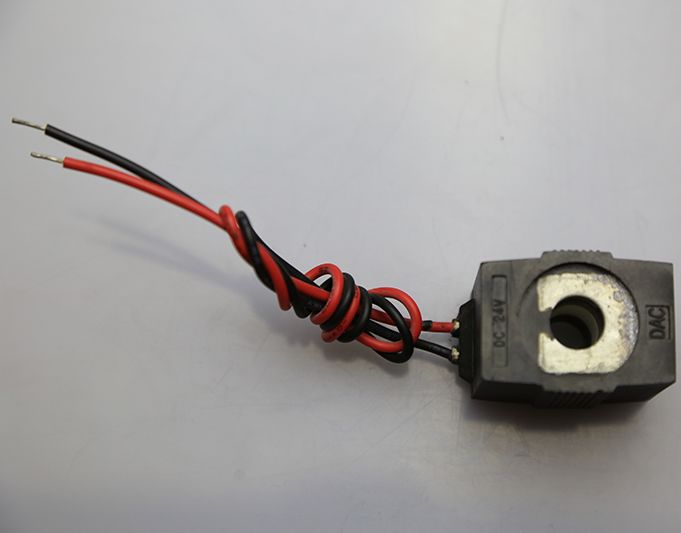

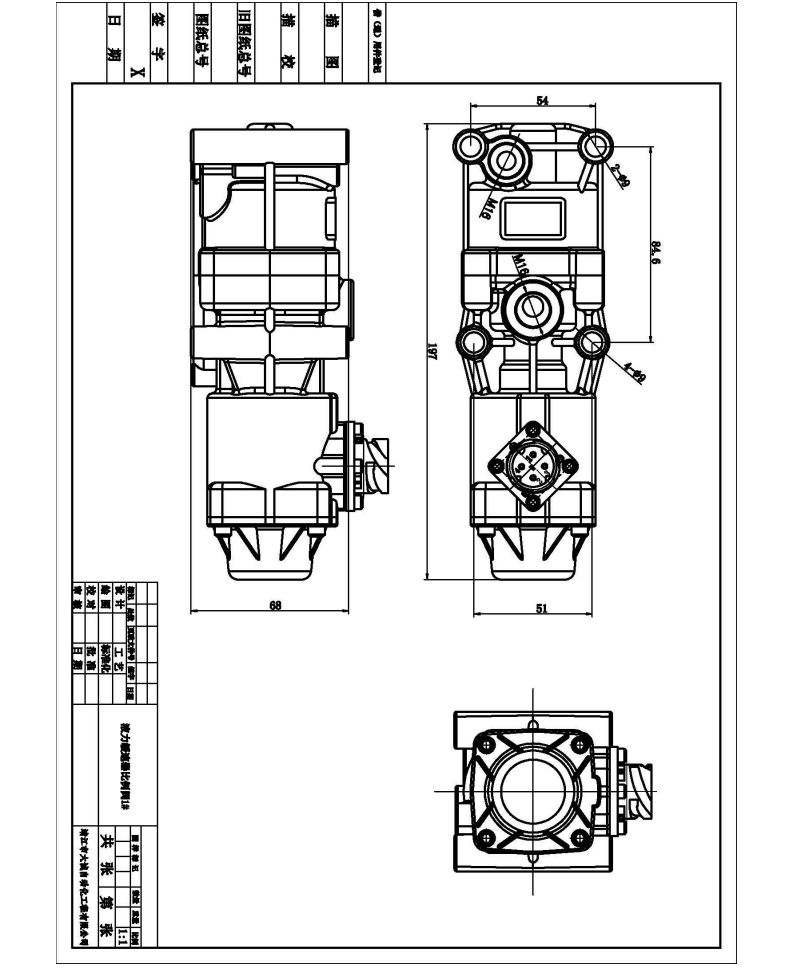

At present, our company has two types of hydraulic retarder proportional valve, one without on-off valve, suitable for 133 type hydraulic retarder, the other with on-off valve, suitable for other types of hydraulic retarder.

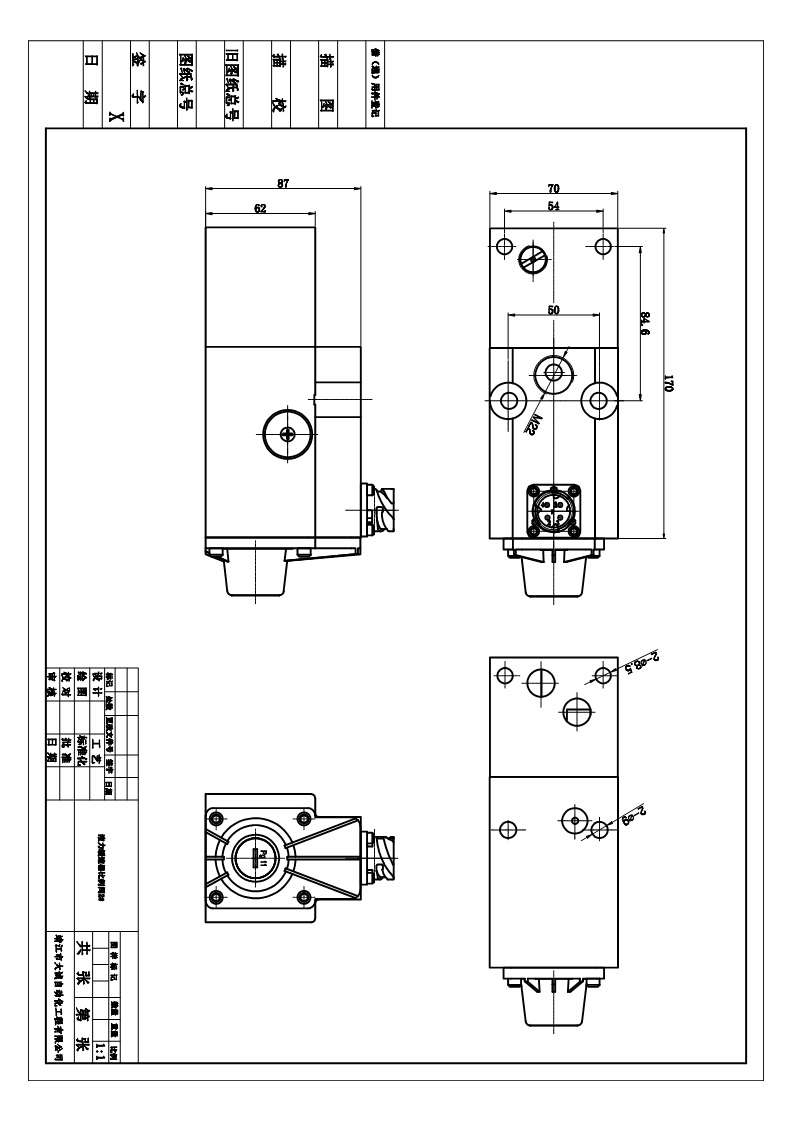

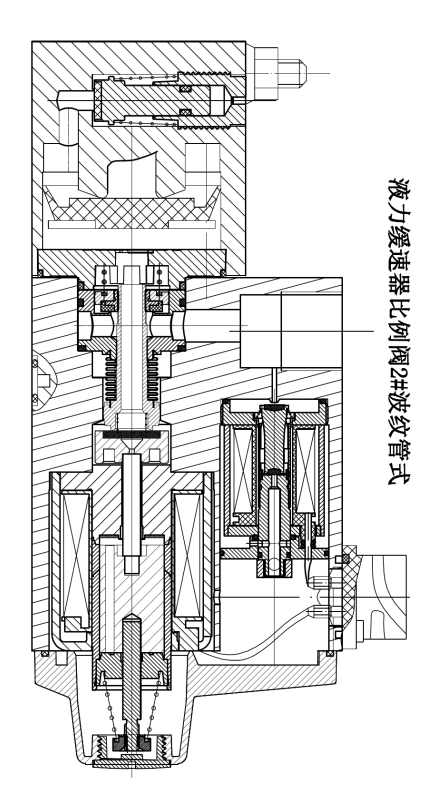

3、相关图纸

4、液力缓速器检测报告

5、相关图纸