1. Introduction of electric control purification condenser

1.1 what is the electric control purification condenser

At present, the brake medium of various types of automobiles in the form of air braking is the compressed air directly provided by the automobile air compressor. Its output temperature can reach more than 160 ℃, which is full of water vapor, oil and other impurities. Without effective treatment, it is directly input into the brake control related devices, causing serious corrosion of the internal metal parts, And once the oil and other impurities adhere to the surface of the moving parts, they can not be discharged in time, which will seriously affect the sealing, use function and working life, resulting in driving safety hazards. In order to overcome the above disadvantages and improve the safety performance of the vehicle, an electric control purification condenser is developed. It can condense and separate the water vapor in the compressed air passing through the condenser, and flow it to the drain outlet of the condenser together with the oil stain. The drain outlet can automatically drain the sewage once every time the vehicle is braked.

1.2 what are the advantages of installing the electric control purification condenser on the vehicle

It can improve the reliability and life of the braking device and the safety performance of the vehicle.

1.3 working principle of electric control purification condenser

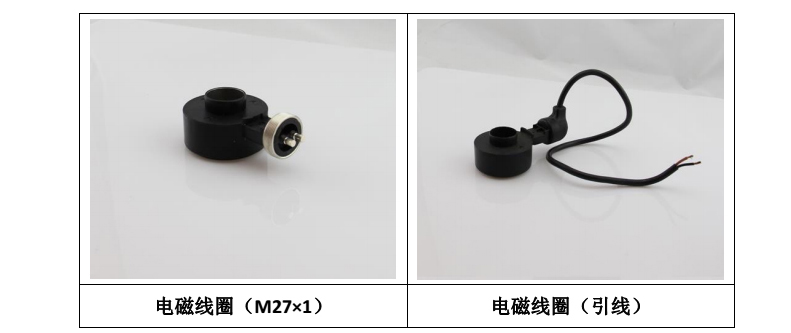

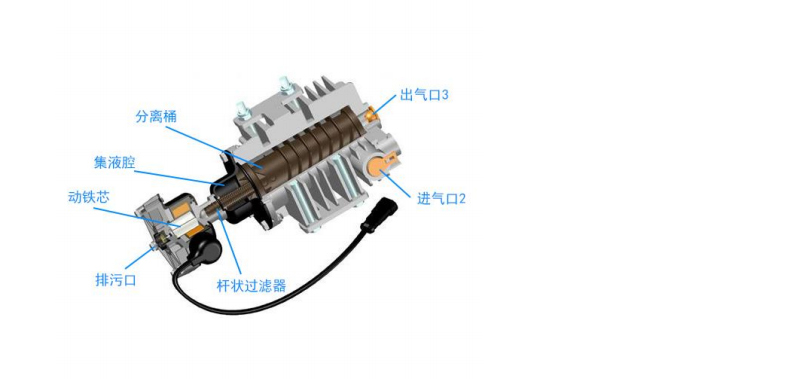

When the compressed air at the temperature of 160 ℃ is input from the air inlet 2, the high-speed spiral motion is generated around the surface spiral groove of the shell and the separation purification cylinder, which makes the water vapor continuously condense and precipitate, and at the same time, it rotates downward together with the impurities such as the oil stain in the air, Under the action of centrifugal force, impurities such as water drops and oil drops with larger molecular weight are continuously separated and purified, and then output from the air outlet 3 through the middle cavity of the separation and purification cylinder for braking. Under the action of air flow, the purified water, oil and other impurities continuously gather in the liquid collection chamber, flow into the vertical groove of the moving iron core through the rod filter to the surrounding of the "O" shaped sealing ring. When each service brake operation is carried out, the electromagnetic coil is connected and connected with 24V DC to generate magnetic force, and the moving iron core is sucked up to make the top of the moving iron core leave the "O" shaped sealing ring, At this time, the impurities such as water vapor and oil pollution are discharged into the air space with a small amount of compressed air. The brake operation is over, the linkage circuit is open, the electromagnetic coil loses power, and the magnetic force disappears. Under the action of self weight, the moving iron core slides down and resets, and the discharge is over. If manual discharge is required, push the push rod of the manual discharge valve upward slightly with fingers, and move the top of the moving iron core away from the "O" ring to realize manual discharge. Stop pushing the push rod of the manual discharge valve, that is to say, the manual discharge is completed and the sealing state is restored.

1.4 main parameters

1.5 installation of electric control purification condenser

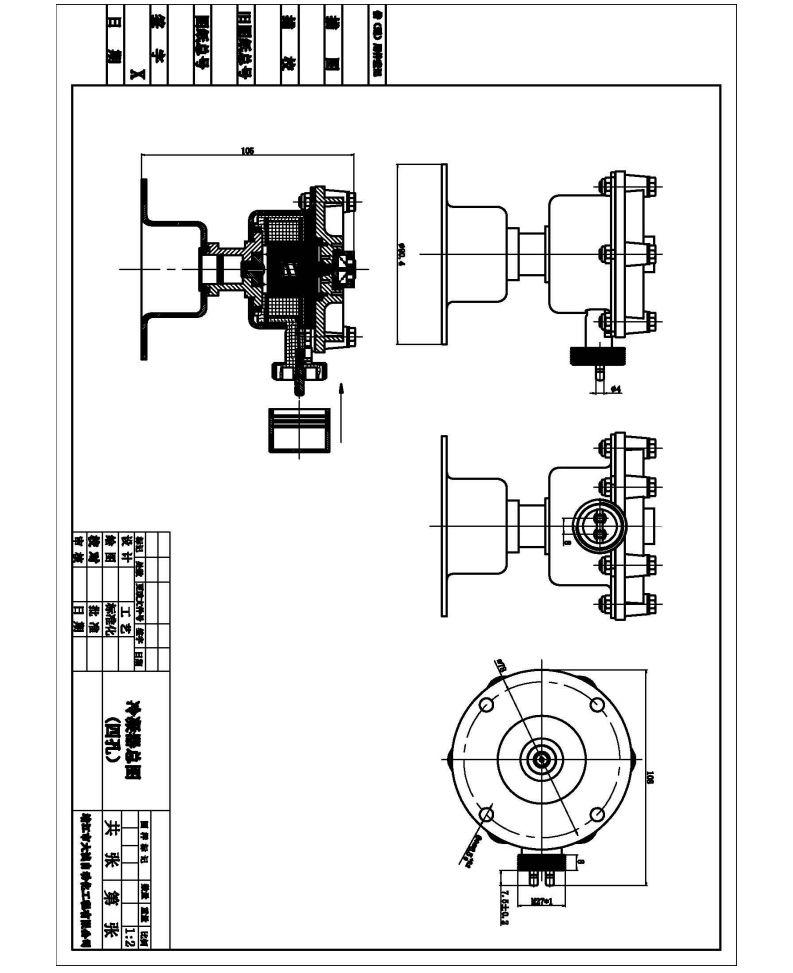

Insert the four M10 bolt ends of the "H" fastening bracket into the corresponding mounting holes of the frame, and then fasten them on the mounting frame with M10 nuts and Φ 10 spring washers. The air inlet npt1 / 2 "on the side is connected with the air compressor outlet with a metal pipe, the length of which is not less than 3m, and the top outlet Npt1 / 2 "is connected with air inlet of air pressure regulating valve, dryer and other devices of automobile brake control device (as close as possible), and can be used.

2. Electric control purification condenser of our company

2.1 photos of relevant products